Shrink fit technology represents one of the highest standards of tool holding in modern CNC machining. Bilz, a global pioneer in tool clamping systems from Germany, delivers world-class shrink fit solutions engineered for extreme precision, rigidity, and superior performance.

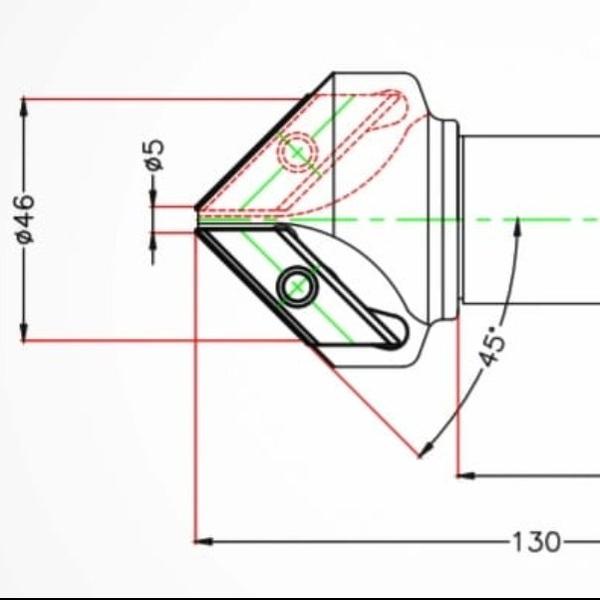

At Indra Engineering Services, we proudly supply Bilz Shrink Fit Holders including the 160 GPL model shown above.

⸻

⭐ What is a Shrink Fit Holder?

A shrink fit holder uses thermal expansion to clamp a cutting tool with exceptional accuracy.

The tool holder is heated (typically using a Bilz ISG shrink machine), the bore expands, the carbide tool is inserted, and as it cools, it contracts to grip the tool uniformly around its entire diameter.

This method provides a full 360° contact between the tool shank and the holder, creating unmatched gripping strength and concentricity.

⸻

🔧 Key Advantages of Bilz Shrink Fit Holders

✔ 1. Ultra-High Clamping Force

Bilz shrink holders generate exceptionally high torque capacity with uniform clamping, ensuring rigid, vibration-free machining even at high speeds.

✔ 2. Maximum Concentricity (≤ 0.003 mm)

Industry-leading runout accuracy provides:

• Better surface finish

• Extended tool life

• Reduced spindle load

✔ 3. High-Speed Stability

Balanced for high RPM applications (25, 000–40, 000 rpm, depending on model), they ensure safe and stable machining at extreme speeds.

✔ 4. Slim Geometry for Deep Cavity Machining

Models like the 160 GPL offer slim, long-reach designs ideal for:

• Mold & die cavities

• Deep pockets

• Narrow machining zones

The smooth surface and taper accuracy ensure consistent tool engagement and minimal deflection.

✔ 5. Superior Surface Finish

Because of perfect runout and rigidity, shrink holders deliver:

• Mirror finishes

• Minimal chatter

• Excellent dimensional accuracy

✔ 6. Maintenance-Free & Long Life

Shrink fit holders have no moving parts, making them extremely reliable with long operational lifespan.

⸻

💡 Applications

Bilz Shrink Fit Holders are widely used in:

• Aerospace components

• Die & mold machining

• Precision automotive parts

• High-speed milling

• Tool rooms and production machining

Perfect for solid carbide end mills, drills, and reamers.

⸻

🏭 Why Choose Bilz Shrink Fit (German Quality)?

Bilz is globally recognized for:

• Precision machining

• Heat-treated alloy steel bodies

• Tight manufacturing tolerances

• Surface finish and taper accuracy

• Consistent clamping even after thousands of cycles

German quality—combined with competitive Indian pricing through local supply—makes Bilz the best in shrink fit technology.

⸻

🤝 Available at Indra Engineering Services

As an Authorised Channel Partner for Bilz, we provide:

• Shrink Fit Holders (GPL, GPR, long, standard & slim types)

• Shrink Fit Machines (ISG series)

• Technical support for selection & application

• Guidance on shrink length, tool diameters & balancing grades

The 160 GPL Bilz Shrink Holder displayed above is one of our most in-demand models for long-reach, high-speed carbide milling.

⸻

📞 Contact: 90470 13803

🌐 www.coimbatorecnctools.in